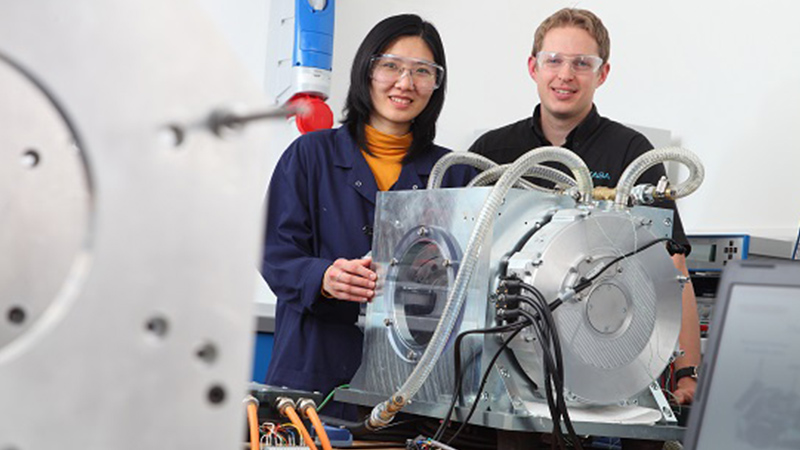

Through its work with one high-performance electric motor manufacturer, the Joining Technology Lab (formerly Joining Technology Research Centre) at Oxford Brookes University has helped the automotive industry make significant progress in the development of electric motors for mass production.

Led by Professor James Broughton, the team has helped YASA Motors to produce more efficient, more reliable, more powerful electric motors that use less material and take less time to make, leading to significant cost reductions for the business and its high-profile clients.

By providing crucial research and development over a more than a decade, James’s team has accelerated progress towards sustainable mass production of next generation electric vehicles, contributing significantly to the UK automotive industry’s progress towards Government targets for the total electrification of transport by 2050.