Principal Investigator(s): Dr Shpend Gerguri

Contact: s.gerguri@brookes.ac.uk

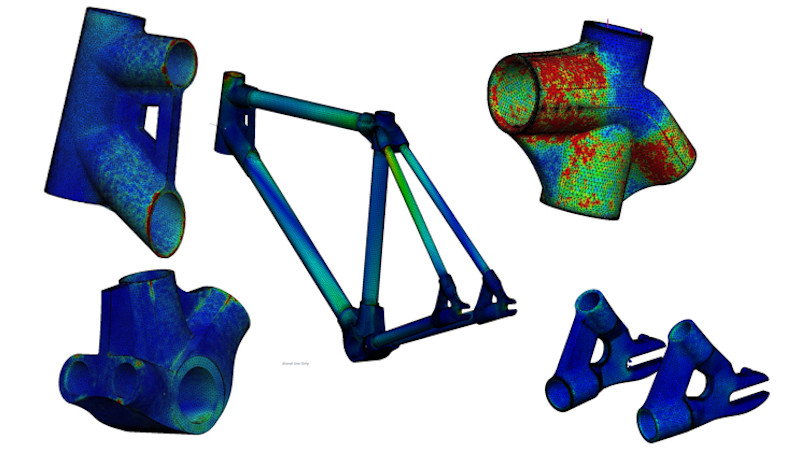

Additive Manufacturing (AM), colloquially known as 3D printing, is being promoted as the spark of a new industrial revolution, associated with potentially strong prospective for sustainable development. The aim of the project was to investigate the possibility of using 3D printed fibre reinforced lugs acting as structural members in the manufacture of a modular bamboo bicycle frame.

The project was in collaboration with Bamboo Bicycle Club based in London as part of the design and development of 'future bike'. The concept was successfully demonstrated whereby a frame and complete bicycle was built "live" at the Design Museum with the first ride taking place on the same day. It demonstrated how integrating engineering principles, additive manufacturing and natural materials can deliver an exciting product.

The primary aim - to manufacture the world's first modular bamboo bicycle frame using 3D printed fiber reinforced lugs - was successfully achieved. The project demonstrated how integrating engineering principles, additive manufacturing and natural materials can deliver exciting products.

The project attracted some great media attention, such as the Global Cycling Network (GCN) and others: